Introduction

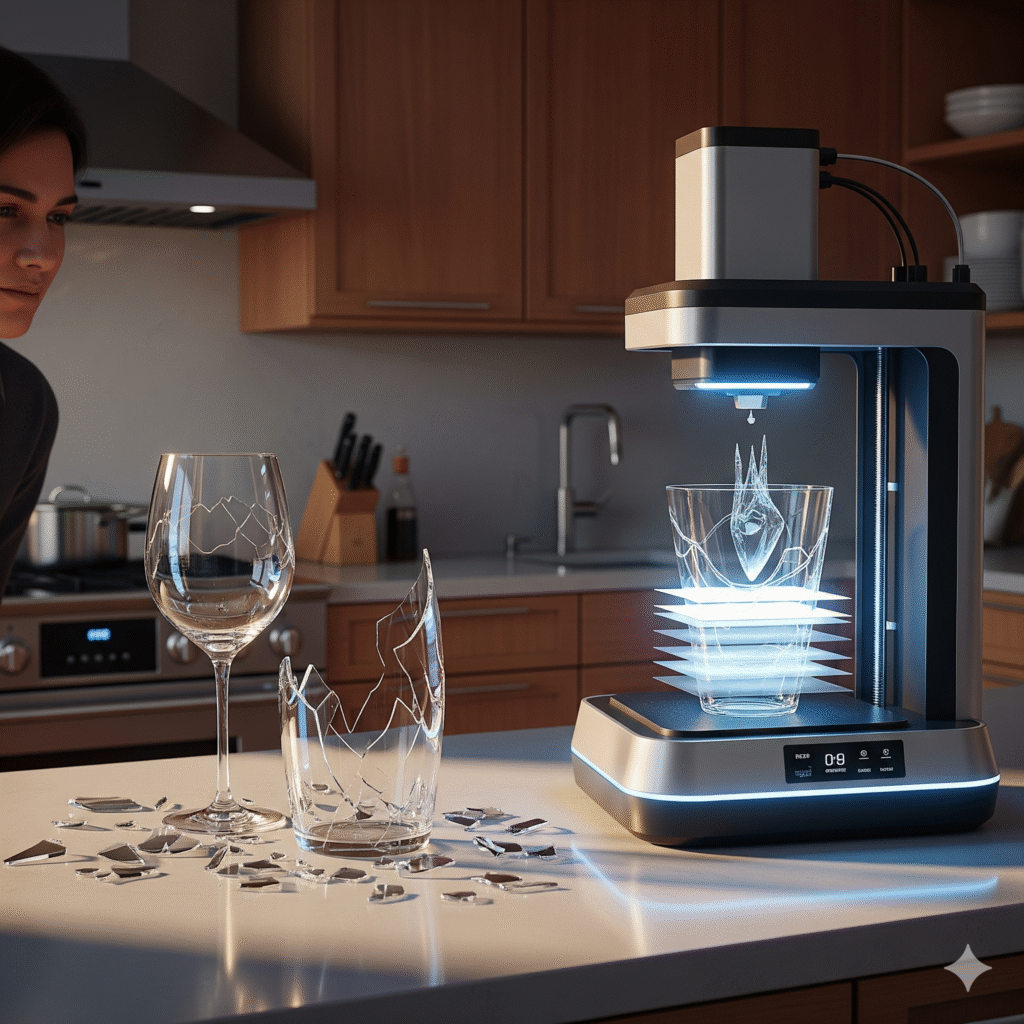

Picture this: you’re washing dishes after dinner, and your favourite glass slips from your hands. The sharp crash of shattering glass cuts through the room, and suddenly you’re left with two problems-sweeping up shards and figuring out where to replace that irreplaceable piece.

What if I told you that in the not-too-distant future, you might not need to head to the store at all? Instead, you could scan the broken glass, press a button, and watch a brand-new one emerge-layer by shimmering layer-from a 3-D glass printer sitting right in your kitchen.

Sounds like something out of a sci-fi novel, doesn’t it? But scientists and designers are already exploring this possibility. And the implications go far beyond saving your wine glass collection.

The Problem: Glass Is Beautiful… but Fragile

Glass is everywhere: the windows we look through, the phones we scroll on, even the solar panels that power our homes. Humanity has been shaping glass for more than 4,000 years. But no matter how advanced we get, one thing hasn’t changed-it breaks easily.

According to the U.S. Environmental Protection Agency, only about 31% of glass in the United States is recycled. The rest ends up in landfills, where it can take thousands of years to decompose. On a personal level, that means countless mugs, bottles, and heirloom vases are lost forever.

I’ll never forget the day I knocked my grandmother’s hand-painted glass tumbler off the counter. No store carried a replacement. No artisan could replicate the sentimental value. I kept the broken pieces in a box for years, wishing there had been a way to bring it back.

That longing for sustainability, for preservation, for second chances-is what makes 3-D-printed glass such an exciting frontier.

How 3-D Glass Printing Actually Works

Let’s demystify the process. Think of it less like magic and more like very precise, very hot craftsmanship.

- Designing the Object

You start with a digital design-either drawn in software like AutoCAD or captured using a 3-D scanner. That broken glass? A quick scan could recreate its exact curves. - Feeding the Printer

Instead of plastic filament, the printer uses silica (the same material as sand), recycled glass powder, or molten glass. - Layer by Layer Printing

A nozzle heated to over 1,000°C extrudes molten glass in thin streams, stacking them into the desired shape. Imagine drawing with liquid fire that cools into transparency. - Cooling and Annealing

Here’s the tricky part: glass needs to cool slowly, or it cracks. Special ovens, called annealers, gradually bring the temperature down. - Finishing Touches

The piece might need polishing, engraving, or tinting-just like hand-blown glass.

Back in 2015, MIT’s Mediated Matter Group unveiled its first “G3DP” printed glass vessels. The glowing, honey-like material flowed through nozzles, solidifying into dazzling forms. Since then, companies like Micron3DP in Israel have been racing to make the technology more practical and scalable.

Traditional Glassmaking vs. 3-D Printing: What’s the Difference?

If glassblowers have been doing this for centuries, why reinvent the wheel? The difference lies in control and customization.

- Traditional glassmaking: requires molds, furnaces, and skilled artisans. Perfect for large batches but limiting for one-off items.

- 3-D glass printing: requires no molds, can produce intricate geometries, and allows rapid prototyping.

Think of it like cooking: traditional glassmaking is like baking dozens of identical loaves of bread in a big oven. 3-D printing is like having a bread machine at home that can whip up a custom loaf just for you-whole wheat, seeded, heart-shaped if you like.

That flexibility makes it appealing not only to homeowners but also to architects, medical researchers, and artists.

Benefits and Real-World Use Cases

The real power of this technology goes way beyond kitchen glassware. Here are some exciting possibilities:

- Everyday Life: Replace a broken cup, vase, or plate with an exact replica-or a completely new design.

- Architecture: Print bespoke windows or sculptural panels directly for buildings. Imagine a library with 3-D-printed stained glass skylights.

- Healthcare: Custom glass lab equipment, optical lenses, or even micro-fluidic devices for medical research.

- Art and Design: Artists could create structures previously impossible with hand tools-spirals, lattices, fractals.

- Sustainability: Instead of tossing bottles, cities could recycle them into printable glass feedstock, closing the loop on glass waste.

I once visited a local maker space in [San Francisco] where members dreamed of offering a “glass print bar.” Imagine ordering a personalized cocktail glass that gets printed while you wait. It’s whimsical now, but it may soon be a business model.

Expert Insights

“Glass printing is not just about replacing what we lose,” says Dr. Neri Oxman, architect and former director of MIT’s Mediated Matter Group. “It’s about unlocking entirely new design languages. Glass becomes programmable-something we can shape with digital precision rather than just heat and breath.”

Industry leaders echo the potential. Micron3DP’s research head explained that printed glass could revolutionize sectors where precision and customization matter most-like optics, aerospace, and medical devices.

FAQs

Q1: Can I 3-D print a drinking glass at home today?

Not quite. Current machines are expensive and industrial-grade. But just as plastic 3-D printers went from labs to living rooms, experts predict smaller, affordable glass printers within the next decade.

Q2: Is 3-D-printed glass safe to use?

Yes-once properly cooled and annealed, it’s as strong and food-safe as traditional glassware. The key is ensuring the cooling process prevents hidden cracks.

Q3: What materials go into 3-D glass printing?

Silica sand, recycled glass powder, or molten glass are the main ingredients. Additives can tweak properties like color, transparency, or even strength.

Q4: How much does a glass 3-D printer cost?

Industrial versions can run tens of thousands of dollars. Like other tech, prices are expected to drop as adoption grows.

Q5: Could 3-D printing reduce glass waste?

Absolutely. By turning waste bottles into printable material, cities could cut landfill use dramatically and move closer to circular recycling systems.

Conclusion

The next time a glass shatters in your kitchen, pause before tossing it. That moment of frustration may one day turn into opportunity. Instead of sweeping up and shopping for replacements, you could feed those shards into a compact printer and watch a brand-new glass form before your eyes.

This isn’t just about convenience. It’s about reimagining glass as something renewable, customizable, and deeply personal. From sustainable cities to artistic breakthroughs, 3-D-printed glass promises to reshape our relationship with one of humanity’s oldest and most fragile materials.

So the next time someone says, “Don’t cry over spilled milk,” maybe you can add, “or over broken glass-because I can just print another.”